Socks Knitting

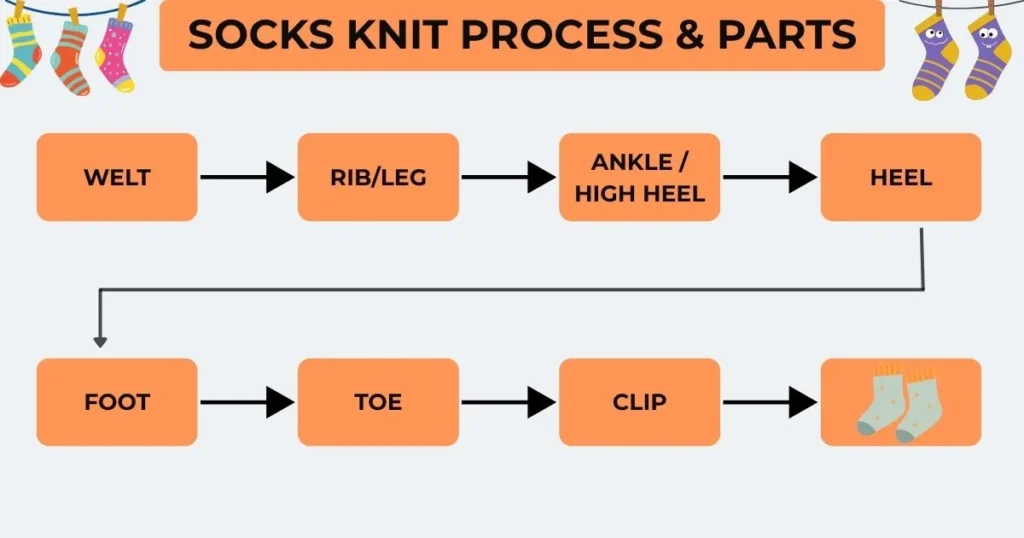

What Is the Socks Knitting Process?

Socks are one of the most worn but least understood items in your wardrobe. You wear them on a daily basis. But have you ever wondered how they’re made?

Here’s the secret: socks aren’t sewn. They’re knit. Just like sweaters but way more precise. The sock knitting process uses circular knitting machines that move fast and stitch even faster. They shape the sock—welt to toe—in a single, continuous motion. No cutting. No stitching. Just pure knit engineering.

From the cuff to the heel, from the footbed to the toe seam—every part has a purpose. Every zone is built with different tension, stitches and sometimes even different yarns. It’s a combination of tech, tradition and tiny details that make your socks fit just right.

Let’s break down each step in the socks knitting process and show you what goes into making that perfect pair.

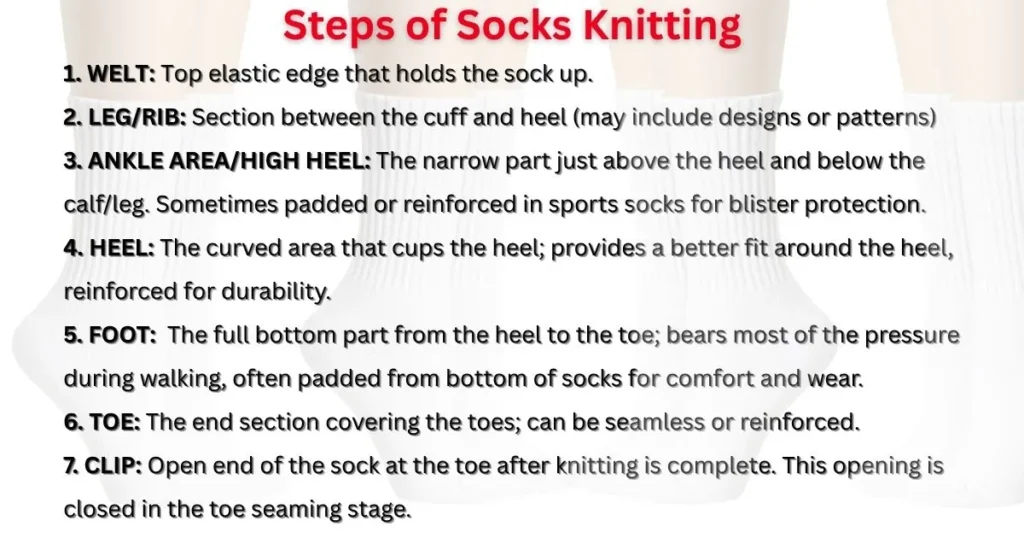

1. Welt – The Sock’s Starting Line

This is where the sock journey begins in socks knitting . The welt is that top band that keeps everything tight. Think of it as the anchor. It’s usually double-layered and built using interlock or tuck stitches to stay flat. No frills, no fancy designs—just pure function. It locks the opening so the sock doesn’t roll down or stretch out over time. Especially important for socks that see daily action. You won’t notice it until it fails then you’ll know why it matters.

2. Rib/Leg – Stretch, Fit, and Style

Next up is the rib, which gives your sock grip and flexibility. It’s made with a combo of knit and purl stitches—think 1×1 or 2×2 or 3×1 ribs construction & etc. Why? Because ribbing clings to your leg. It expands and contracts like a mini spring. After the welt, we hit the leg section, where designs and logos come into play. This is where sock companies show off—branding, stripes, colors, you name it. The leg length varies by style (crew, mid-calf, thigh-high) but the knitting remains steady and smooth. This part is built for both function and fashion.

3. Ankle/High Heel – The Turning Point

Now we reach the ankle, also called the high heel area. This part narrows slightly and acts like a bridge between the straight leg and the shaped heel. The yarn tension is adjusted here for a snugger fit. Why? Because your ankle bends. You don’t want baggy fabric bunching up every time you move. Some socks add stretch yarn (like elastic) here for light compression. It’s not flashy but this section is key to keeping the sock in place all day long.

4. Heel – Built for Impact

The heel takes the most beating, so it needs special attention. This part is knit using reciprocating (back-and-forth) motion, not the standard spiral. That lets the machine shape the curve of the heel. Common types? Y-heel, real heel, and pouch heel—each offering a slightly different fit and feel. Heels are often reinforced with stronger yarns (like nylon or polyester) because they’re the first to wear out. A good heel hugs your foot, doesn’t bunch and lasts longer. That’s what separates cheap socks from great ones.

5. Foot – The Sock’s Main Body

After the heel is done, the machine switches back to circular knitting to crank out the foot section. This is the longest stretch from heel to toe and it needs to be smooth, durable and comfy. Some socks add terry loops here for cushioning, especially in sports or hiking models. Others keep it sleek for a low-profile fit. You might also find compression bands knitted in for arch support, this is where comfort and performance collide.

6. Toe – The Final Shape

The toe is where the sock narrows again to match your foot’s shape. It’s built using short-row or reciprocating knitting, just like the heel. But here’s the twist: it has to taper smoothly to avoid pressure points. Once the shape is made, the toe is closed either with a Rosso machine for a flat seam or by hand-linking in high-end socks. That closure makes a big difference. Seamless toes reduce rubbing and make socks feel like a second skin.

7. Clip – Time to Wrap it Up

In the last step of sock knitting process, the term “clip” refers to the open end at the toe of the sock that remains unfinished after that knitting is completed. Socks are typically knitted in a tubular form, starting from the top (welt) and progressing downward toward the toe. When the knitting reaches the end of the toe section, the machine leaves an open edge this is known as the clip. At this stage, the sock cannot be worn yet, as the toe area is not sealed.

The clip must be closed during a process called toe seaming or toe linking, where the opening is stitched shut. This can be done using various methods, such as machine linking (like Rosso machines) or hand linking, depending on the quality level desired. Seamless or fine-linked toes are often found in premium socks, offering greater comfort and reducing irritation. Properly finishing the clip is essential to ensure the sock is fully functional and comfortable for the wearer.

Note:

With the advancement in sock knitting technology, some modern machines (like classic linking machines) are now capable of automatically closing the toe during the knitting process. This eliminates the need for a separate toe-closing step, resulting in a smoother, faster and more efficient production process but this sock is slightly expensive as compared to open-toe sock.

FAQs

Final Thoughts

The sock knitting process is more than just thread and loops. It’s a blend of precision, programming and design. Every sock goes through a detailed journey—from the welt to the toe, from plain tubes to perfectly shaped foot-huggers.

Whether it’s for style, sport or comfort, socks are engineered to perform. And it all starts with how they’re knit.

So next time you slip on a pair, just know—there’s a whole system behind that softness, stretch and snug fit. And now, you understand exactly how it’s made.