Embroidery Socks

What are Embroidery Socks

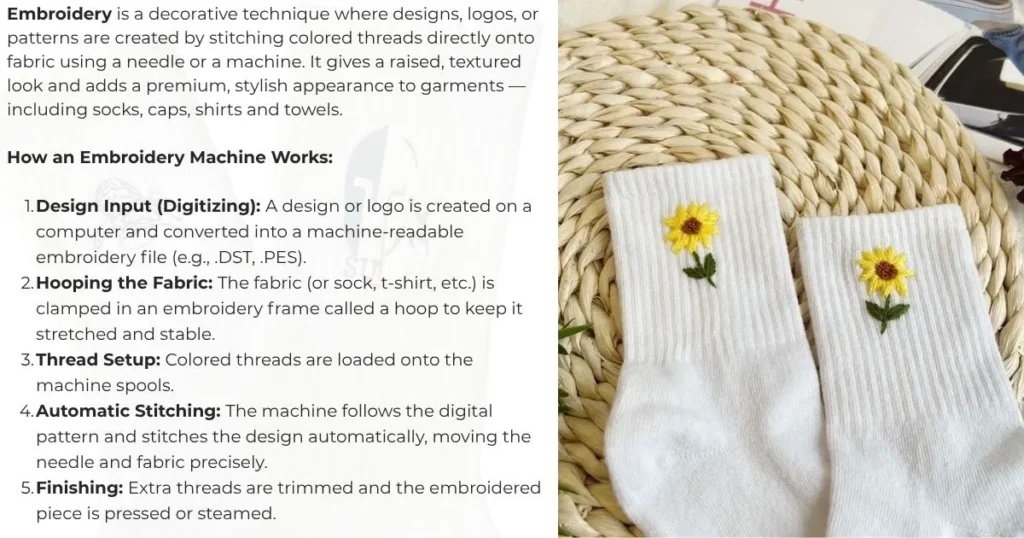

Embroidered socks are socks that feature decorative stitched designs, made by using colourful threads to create patterns, logos, or artwork directly onto the fabric. Think of them as regular socks with personality stitched in.

They’re not printed or dyed; the design is sewn into the sock using embroidery machines or hand stitching. That’s what makes them stand out. The thread adds a textured, raised look that feels premium and lasts longer than printed graphics.

Let’s break it down:

What Makes Embroidery Socks Special

- Design Method: Unlike printed socks, embroidery involves actual thread stitched into the surface.

- Texture: You can feel the design. It’s slightly raised and more durable.

- Look: Gives a classy, 3D finish — often used for logos, initials, flowers or quirky icons.

- Durability: Embroidered areas don’t fade or peel easily because they are an integral part of the fabric.

How They’re Made

- Base Sock Creation: The sock is knitted first (usually cotton, polyester, spandex or a blend).

- Design Setup: The embroidery design has been digitized and loaded into an embroidery machine.

- Stitching: High-speed needles stitch the pattern directly onto the sock.

- Finishing: Threads are trimmed, the sock is steamed, checked for quality and packed.

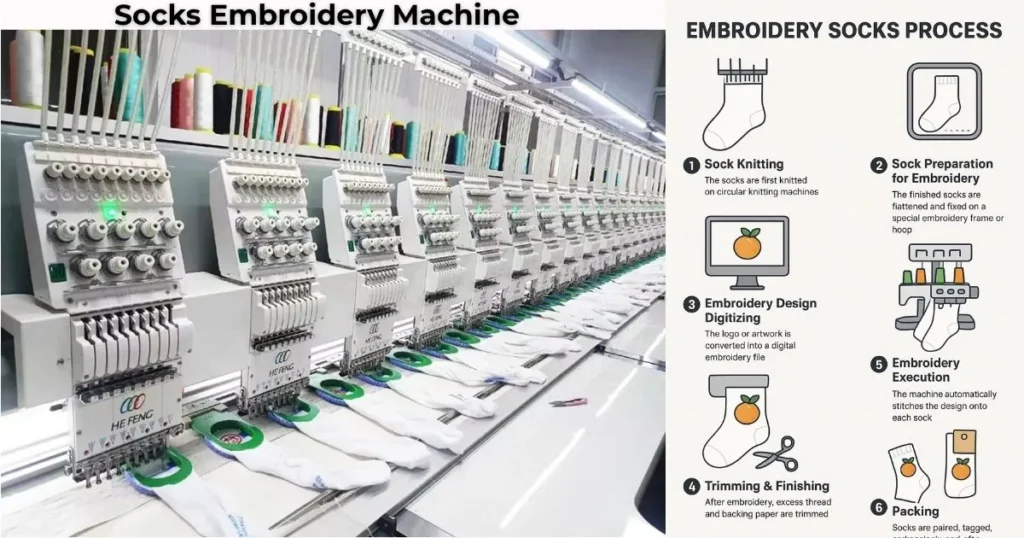

How an Embroidery Machine Works

Let’s keep it simple. An embroidery machine is basically a robot that sews art. It stitches thread rather than printing colours; it is quick, precise and repeatable.

Here’s how it really operates:

1. Design Digitizing

Everything starts with a digital design file. You can’t just upload a photo—the image must be converted into stitches using special software (like Wilcom, Tajima DG or Brother PE-Design).

This process tells the machine:

- Where to start stitching.

- What direction each thread runs.

- Which color comes next.

- How many stitches are needed.

This the file is known as a DST or PES file, depending on the brand. It functions like a map for the machine, guiding each needle movement.

2. Thread Setup

Next, you load colored embroidery threads into the machine’s spools. Each needle can hold one color—and advanced machines have 6, 12, or even 15 needles, meaning they can switch between colors automatically. No stopping. No manual thread changes. Just speed.

3. Hooping the Sock

Now, the challenging part is securing the sock in position. Since socks are stretchy and round, regular frames aren’t effective. That’s why sock embroidery machines use circular frames or specialized clamps to grip the sock tightly without warping it. This keeps the surface flat and smooth for perfect stitching.

4. Machine Calibration

Before stitching starts, the operator checks:

- Thread tension (too tight → tears, too loose → messy lines)

- Needle alignment

- Stitch density

This ensures clean, sharp embroidery, especially on elastic socks.

5. Automatic Stitching

This is where the magic happens. When the design file is loaded and the sock is hooped, the machine begins sewing automatically.

- Motors move the hoop in X and Y directions.

- Needles punch up and down hundreds of times per minute.

- Threads change automatically when the design calls for a new color.

It’s precision engineering, turning digital code into physical art, stitch by stitch. A single design can have anywhere from 2,000 to 20,000 stitches, depending on complexity.

6. Trimming and Finishing

When the embroidery is done:

- Extra threads are automatically trimmed.

- Socks are removed from the hoop.

- The design area is steamed to remove wrinkles.

- Finally, each pair is quality-checked for thread breaks or alignment issues.

Fun Fact:

Professional multi-head embroidery machines can produce 6 to 20 socks at once, all with identical designs, making them perfect for mass production.

Why It Matters for Socks

Socks aren’t flat like t-shirts. They stretch, bend and curve. That’s why sock embroidery machines have to be ultra-precise with tension and hopping. One wrong pull and the design can distort when worn.

So, every embroidered sock you see with that tiny smiley face, logo or heart went through an exact, automated dance between software, needles and fabric tension.

Embroidery Machines and Types of Embroidery Machines

Embroidery Socks are made on a variety of machines. Different embroidery machines handle different production needs. Here’s how they vary:

| Type | Description | Common Use |

| Single-Head Machine | One embroidery head, usually with multiple needles (6–15 colors). | Small businesses or sample production. |

| Multi-Head Machine | Multiple heads that embroider the same design simultaneously. | Mass production in factories. |

| Flat Embroidery Machine | Works on flat fabrics like t-shirts, patches, or towels. | Garments, fabric panels. |

| Cap Embroidery Machine | Built with a curved frame designed for caps and hats. | Sportswear, uniforms. |

| Sock Embroidery Machine | Special setup for round, elastic socks. | Socks and hosiery. |

| Computerized Home Embroidery Machine | Compact, user-friendly versions for personal or small-scale use. | Custom orders, crafts. |

Sock embroidery machines are specially designed for the cylindrical shape and elasticity of socks. They use flexible frames or clamps to keep the sock tight while stitching—ensuring designs stay smooth and centered even when stretched.

Embroidery Logo vs Knitting Logo

Both look cool on socks, but they’re made completely differently. One is stitched on top, the other is built inside the fabric.

| Feature | Embroidery Logo | Knitting Logo |

| Process | Stitched on finished sock | Woven during knitting |

| Texture | Raised, 3D feel | Flat, smooth |

| Detail Level | Very detailed | Limited detail |

| Durability | High (but can snag) | Extremely durable (part of the fabric) |

| Color Variety | Up to 15+ thread colors | Limited to machine yarn feeders |

| Cost | Higher (extra process) | Lower (included in knitting) |

| Look | Premium and eye-catching | Clean and sporty |

| Used For | Fashion, branding, luxury | Athletic, casual, uniforms |

Note:

The cost of embroidery depends on the number of stitches and the size of the design. A larger logo or detailed pattern requires more stitches, more time and more thread, which means a higher production cost.

Why Choose Embroidery Socks Over Printing

Embroidery socks beat printed ones hands down.

- More Durable: Embroidery uses stitched thread, not ink. It won’t fade, peel or crack after washing.

- Premium Look: The 3D texture looks richer and feels high-quality.

- Longer Lasting Branding: Logos stay sharp for years, perfect for building brand trust.

- Detail Precision: Tiny icons, initials, or logos look crisp and clean.

- Chemical-Free: No dyes or heat transfers, just thread and craftsmanship.

Printing is fast. Embroidery lasts.

Conclusion

Embroidered socks aren’t just another pair of socks; they’re a statement of quality and style. With durable stitching, a premium 3D look, and long-lasting designs, they stand miles ahead of printed options. Whether you’re building a brand, creating custom merch or just want socks that look and feel high-end, embroidery socks deliver both beauty and durability in every stitch.