Single vs Double Cylinder Socks

The Full Breakdown: Single vs Double Cylinder Socks

When it comes to socks, most people only think about the colour, size, or maybe the fabric. But here’s what matters—how it’s made.

Behind every sock is a machine. And the type of machine used determines almost everything about how that sock will fit, stretch, breathe and hold up over time.

The two main types? Single cylinder and double cylinder.

The names sound technical but don’t worry—we’ll break it down in plain English. This isn’t a lesson in machinery. It’s a guide to what touches your skin every day.

What is a Sock Cylinder?

A “cylinder” is the rotating drum in a sock knitting machine that holds rows of needles. These needles knit your sock in a spiral, one loop at a time.

- Single cylinder = one set of needles in a single circle.

- Double cylinder = two sets of needles, one on top and one below, stacked in layers.

1. Single Cylinder Socks

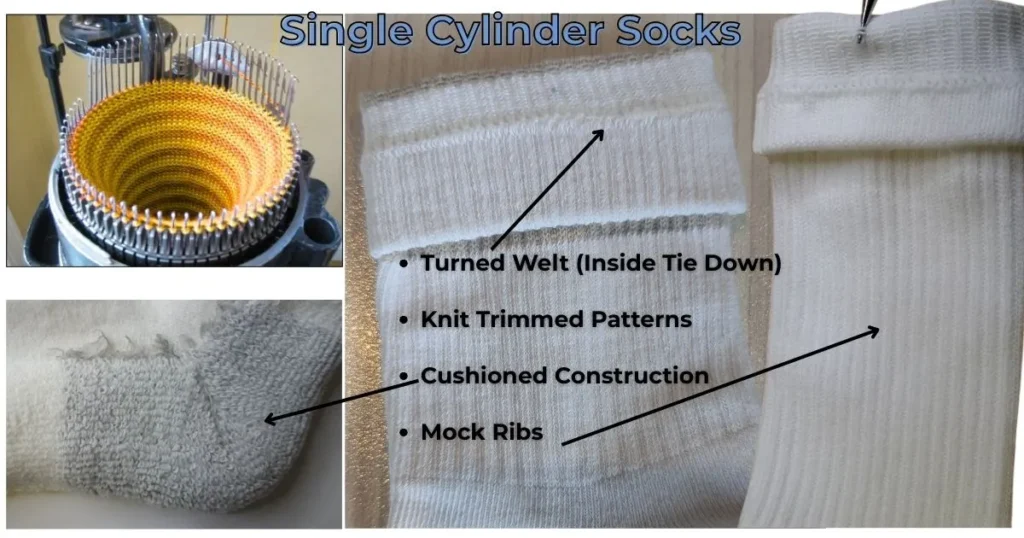

Single cylinder machines are the foundation of the sock world. They’re fast, affordable and produce the most common sock styles you’ll see on the market. Built with one circular needle bed, these machines are designed to knit tube socks or socks with simple Y-shaped heels. Their output is ideal for casual, everyday wear, making them a go-to choice for budget and bulk production.

The key features found in socks made on single cylinder machines are:

- Turned Welt (Inside Tie Down): The top cuff is folded and tied down inside for a neat finish.

- Knit Trimmed Patterns: Simple, cost-effective patterns created during knitting.

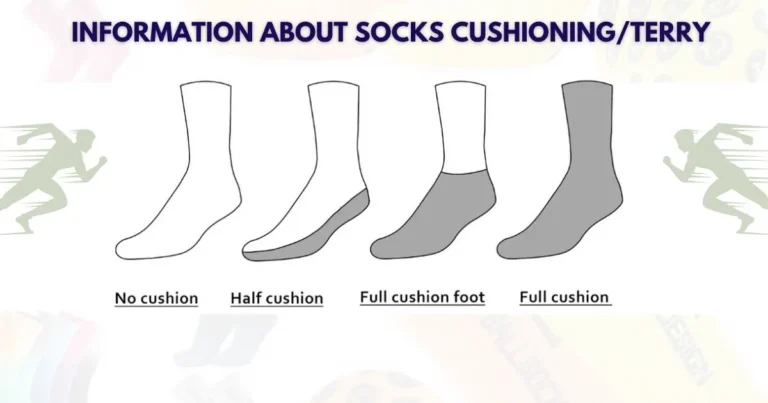

- Cushioned Construction: Extra loops added for soft underfoot feel—common in athletic and work socks.

- Mock Ribs: Visual rib texture but not true ribbing—gives stretch without real grip.

Single cylinder socks are perfect for budget-conscious, bulk and basic performance requirements. You’ll see them in school wear, sports packs and cost-effective work socks. While they may lack premium quality, they perform well—quickly and affordably.

Pros:

- Faster production: cheaper socks.

- Good stretch: fits multiple foot shapes.

- Wide Range of Styles: can Produce casual, sports and stylish ones, in different lengths and complex patterns.

Cons:

- Limited structure: they lack ribbing.

- Cuffs may slide: no tight grip on the ankle.

- Less Fit Precision: Typically lacks the precision of double cylinder socks in terms of fit and structure.

Best for:

Budget-friendly bulk socks. Think big packs in department stores or simple uniforms.

2. Double Cylinder Socks:

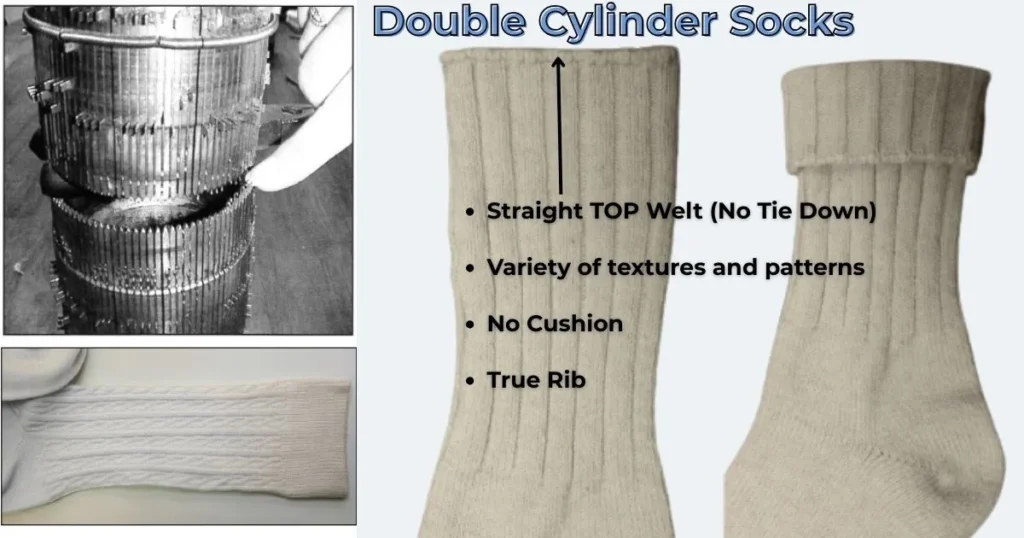

Double cylinder sock machines are built with two needle beds, giving manufacturers far more control over stitch structure and sock design. This setup allows the machine to knit true ribbing, which grips the leg better and to shape heels for a more contoured fit. With this added precision, double cylinder machines can create multiple textures, functional zones, and a noticeably better overall fit—perfect for premium or performance socks.

The features of socks made on double cylinder machines are:

- Straight TOP Welt (No Tie Down): Clean, flat finish at the top with no turned welt.

- Variety of Textures and Patterns: Advanced needle control allows for cable knits, ribbed zones, and stylish patterns.

- No Cushion: Most styles are sleek and flat, perfect for dress or formal wear.

- True Rib: Genuine 1×1 or 2×2 or 3X1 & etc… rib structure for better stretch and grip.

These socks are often found in premium collections, dress lines, and performance wear, where comfort and hold are prioritized over bulk cushioning.

Pros:

- Stay-up cuffs that don’t sag.

- Can produce true ribbed styles (like 1×1 or 2×2 ribs), which are stretchable and comfortable.

- Good for more complex patterns, including detailed jacquard and mesh zones.

Cons:

- Slower production = higher price tag.

- More complex manufacturing = requires better quality control.

Best for:

Dress socks, medicated socks, sports performance gear and luxury brands.

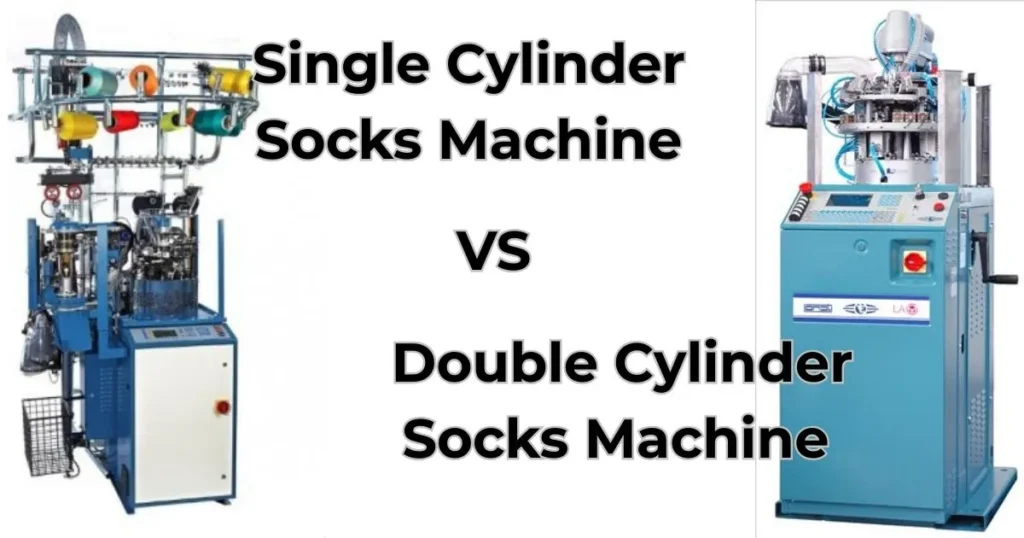

Single vs Double Cylinder Sock Machines

1. Single-cylinder machines

Single-cylinder machines use one circular bed of needles. They knit basic socks like tube socks, casual everyday styles, cushioned sole and low-cost multipacks. These machines are fast, simple, and ideal for mass production—but they lack structure. Socks made this way can stretch to fit but often slide down or bunch up.

2. Double cylinder machines

While there are rare exceptions, double cylinder machines usually can’t knit cushioned socks. They specialise in producing true rib fabrics using a two-cylinder setup. The needles move vertically with sliders, forming rib stitches (back loops) when the top cylinder is engaged and frame stitches (face loops) when the bottom cylinder is active. These sliders run in cam tracks around both cylinders, enabling precise knitting control. These machines produce high-quality socks with a better fit, better hold, and more durability. They’re slower and costlier but perfect for premium, dress or performance socks.

| Feature | Single Cylinder | Double Cylinder |

| Needle Setup | One set of needles in a single cylinder | Two sets in stacked inner & outer cylinders |

| Sock Style/Ideal For | Basic, tube, casual, basic fashion, athletic socks | Ribbed, Dress, premium, medical & detailed fashion socks |

| Rib Knitting | Not possible | True rib 1×1, 2×2, 3×1 & etc.. |

| Design Complexity | Simple patterns, logos and stripes | Complex jacquard, mesh, and multi-color designs |

| Production Speed | Fast, efficient | Slower, more precise |

| Cost to Operate | Low | High |

| Fit & Comfort | Loose, generic fit | Tailored, snug fit |

| Best For | Bulk, budget socks | Premium, branded, technical socks |

Which machines are frequently used?

Single cylinder machines are faster and simpler. They can churn out thousands of socks a day with minimal downtime. That’s why you’ll find them in:

- Bargain brands

- Basic and school socks

- Athletic socks in value packs

- Workwear and performance lines

But what you save in price, you pay in longevity. These socks stretch fast, lose grip, and don’t last as long.

Why Premium Brands Use Double Cylinder Technology

Walk into a luxury store, and you’ll notice the socks simply feel… better. That’s because double-cylinder machines enable:

- Tighter control over tension

- Reinforced toes and heels

- Zoned comfort and compression

- Precision designs and textures

Brands focused on performance (running, hiking) or aesthetics (dress wear) use this method to deliver socks that don’t just fit—they perform.

Final Thoughts:

The Sock Doesn’t Lie. Every sock tells a story. A single cylinder sock says, “I get the job done.” A double-cylinder sock says, “I’m here for the long haul.” So which one’s better? Neither. It depends on your feet, your budget and your purpose. If you’re going to the gym, working construction or just lounging around the house, a single cylinder works.

But if you need compression, comfort, and long-term wear, a double cylinder is worth the upgrade. Your feet do the heavy lifting every day. They deserve socks that match the mission.